Boron carbide

Boron carbide is a compound that contains boron and carbon, especially B4C; an extremely hard, non-metallic, black crystalline compound or solid solution. Only diamond is harder. In addition to its hardness property, boron carbide has the physical properties of corrosion resistance, heat strength, low specific gravity and high elastic modulus. It is used as an abrasive, neutron absorber for nuclear reactors, and as an alloying agent in composite structural materials.

Chemical Composition

| Size | Approx Size(microns) | Chemical Composition(%) | |||

| B% | C% | Fe2O3 | B4C% | ||

| F36 | 600-500 | 78-81 | 17-22 | 0.2-0.4 | 97-99 |

| F40 | 500-425 | 78-81 | 17-22 | 0.2-0.4 | 97-99 |

| F46 | 425-355 | 78-81 | 17-22 | 0.2-0.4 | 97-99 |

| F54 | 355-300 | 78-81 | 17-22 | 0.2-0.4 | 97-99 |

| F60 | 300-250 | 78-81 | 17-22 | 0.2-0.4 | 97-99 |

| F80 | 212-180 | 78-81 | 17-22 | 0.2-0.4 | 97-99 |

| F100 | 150-125 | 78-81 | 17-22 | 0.2-0.4 | 97-99 |

| F120 | 125-106 | 78-80 | 17-22 | 0.2-0.4 | 96-98 |

| F150 | 106-75 | 78-80 | 17-22 | 0.2-0.4 | 96-98 |

| F180 | 75-63 | 78-80 | 17-22 | 0.2-0.4 | 96-98 |

| F230 | 53.0±3.0um | 77-80 | 17-22 | 0.3-0.5 | 96-97 |

| F240 | 44.5±2.0um | 77-80 | 17-22 | 0.3-0.5 | 96-97 |

| F280 | 36.5±1.5um | 77-80 | 17-22 | 0.3-0.5 | 96-97 |

| F320 | 29.2±1.5um | 76-79 | 17-21 | 0.3-0.6 | 95-97 |

| F360 | 22.8±1.5um | 76-79 | 17-21 | 0.3-0.6 | 95-97 |

| F400 | 17.3±1.0um | 75-79 | 17-21 | 0.4-0.8 | 94-96 |

| F500 | 12.8±1.0um | 76-79 | 18-22 | 0.3-0.7 | 94-97 |

| F600 | 9.3±1.0um | 74-78 | 17-21 | 0.4-0.9 | 92-94 |

| F800 | 6.5±1.0um | 74-78 | 17-21 | 0.4-0.9 | 92-94 |

| F1000 | 4.5±0.8um | 75-78 | 18-22 | 0.1-0.8 | 90-94 |

| F1200 | 3.0±0.5um | 75-78 | 18-22 | 0.1-0.8 | 90-94 |

| F1500 | 2.0±0.4um | 75-78 | 18-22 | 0.1-0.8 | 90-94 |

| F2000 | 1.2±0.3um | 75-78 | 18-22 | 0.1-0.8 | 90-94 |

Physical Properties

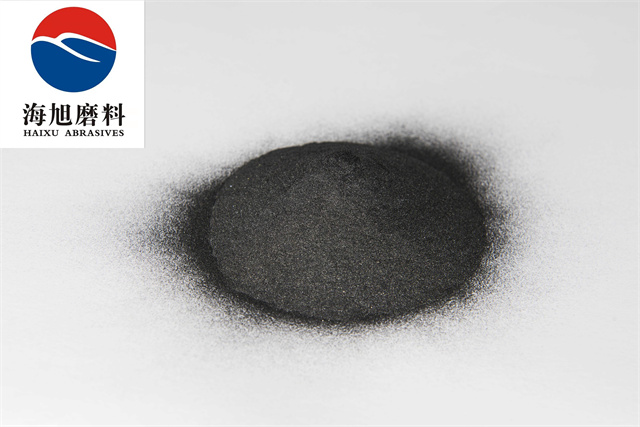

| Appearance | Black powder |

| Molecular Weight (g/mol.) | 55.25515 |

| Specific Heat (cal-mol-c) | 12.5 |

| Knoop Hardness | 2750 |

| Mohs Hardness | 9.6 |

| Micro Hardness | 4950kgf/mm2 |

| Density & phase | 2.52 g/cm (Solid) |

| Melting point | 2350 °C (2623.15 K) |

| Boiling point | >3500 °C (>3773.15 K) |

| Solubility In Water | Insoluble |

| Crystal Structure | Rhombohedral |

Application

- Boron Carbide is well suited to a variety of industrial applications including:

- Abrasives for lapping and ultrasonic cutting

- Anti-oxidant in carbon-bonded refractory mixes

- Armor

- Nuclear applications such as reactor control rods and neutron absorbing shielding

- Wear parts such as blasting nozzles, wire-drawing dies, powdered metal and ceramic forming dies, thread guides